The slip forming process, invented and patented by the founder of Soprel M. Sechoy, has been our preferred production method from day one some 40 years ago. Ever since, SOPREL Engineers and Technicians have constantly increased the productivity and versatility of the production equipment.

Having supplied many international customers with a full range of rugged and reliable, “made in Lebanon” equipment that is built to the “European Certified Standards”, SOPREL is also very well regarded for

design, build and supply of efficient and cost effective precast factories.

SOPREL markets its products and its technological know-how around the globe for the benefit of other concrete producers.

It designs and manufactures a comprehensive range of concrete production machines, installs complete production lines

and provides technical support to external customers.

Know-how transfer is one of the strengths of SOPREL which gives it the ability of planning the entire production lines or even complete factories. It is comprised of a slipformer, a topping

machine, a multi-angle sawing machine, a multi-functional

trolley, a transporter with silos bus machine and a Cleaning

machine. SOPREL grants customers the advantages of flexibility and ease-of-use making it easy to handle and operate.

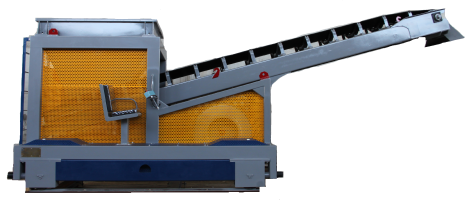

SOPREL Slipformer Machines manufacture 120cm or 240 cm widths for precast hollow core with thicknesses ranging from 120mm to 500mm. This machine allows easy and quick exchange of moulds to produce a wide range of products such as, poutrelles, lintels, cills, walls... foundation piles, U beams, and irrigation channels

Stressing Abutments are conceived for the required pre-stressing strands over the attached Casting Beds

Transporter + Silos Bus the transporter is for timely delivery of the concrete from the silo bus and deliver it to the slipformer

Precast Sawing Machines enable the producer to cut cured hollow core slabs upon the desired length.

Fully Automatic Machine for Cutting and Removal of interslab

Carrier for Plastic Covering: provides covering and thermal protection Cover sheets of high density polyethylene.

Concrete Bucket: transports concrete from the batching and mixing plant to the casting point by means of a crane.

Set of steel mould with fixed central web and adjustable sides and abutments for the multi strands stressing that can sustain a capacity of 800 Tons

Oil heating system

Equipment for tension and de-tension of prestressing strands (Made in Germany) (Known as the Rolls Royce of prestressing equipments)